This machine is principally used in industrial trades rather than shoe manufacturing but there are applications in the shoe industry such as the setting of ventilation eyelets in tennis and basketball shoes for which it is especially adaptable. It comes single or double action where it can cut a hole in the material and set the eyelet/grommet in 2 strokes. Its sturdy, versatile design permits setting several eyelets simultaneously.

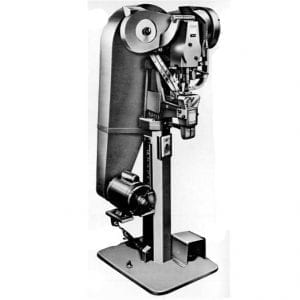

United Model F: Eyelet / Grommet Machine

Description

This eyelet / grommet machine is principally used in industrial trades rather than shoe manufacturing but there are applications in the shoe industry such as teh setting of ventilation eyelets in tennis and basketball shoes for which it is especially adaptable. Its sturdy, versatile design permits setting several eyelets simultaneously. Its horn type of construction provides means for eyeletting at points not accessible on many other types of machines.

It will set all sizes of eyelets, grommets and washers up to the No. 5 Grommet. Strong, heavy and simple in design it exerts a setting pressure of 4,800 pounds.

The machine can be equipped to punch holes as well as set the ventilating eyelets in tennis and basketball shoes. In most other cases, the holes must be punched prior to the eyeletting operation. Manual spacing is necessary. The macine automatically feeds the eyelets. If washers are used they must be hand fed.

Samles of work should be furnished for specific quotations if standard fittings do not meet requirements.

Specifications

| Install Space | 19″L x 58″D |

| Length | 19″ |

| Depth | 34″ |

| Height | 34″ |

| Crated | 27″ x 40″ x 40″ |

| Net Weight | 476lbs. |

| Gross Weight | 556 |