These machines are designed for inserting eyelets or grommets in fabric or similar material without first punching a hole. Machines host an automatic clamper mechanism. The No. 482 Dual Feed can also insert telescoping eyelets and neck washers.

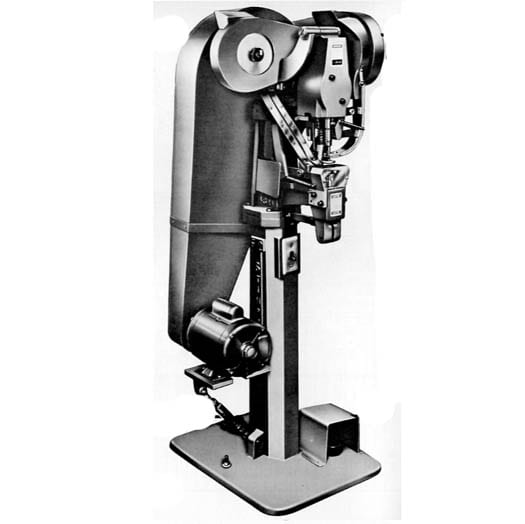

Stimpson No. 482 Dual Feed: Automatic Electric Eyelet / Grommet Machine with Automatic Clamper

Description

These eyelet / grommet machines are designed for inserting eyelets or grommets in fabric or similar material without first punching a hole. The automatic clamper is part of the mechanism of these machines. The No. 482 Dual Feed can also insert telescoping eyelets and neck washers.

Operation

The material is held by the operator in position over the setting tool on top of the bottom clamper. When the foot switch is pressed, the clamper comes down and clamps the material firmly and then the spear point of the bottom set pierces the hole. While the top set is moving down, the eyelet or grommet is picked up by the top set spindle and forces the eyelet or grommet through the material, then completes the setting. With the Double Action machine: by an upward movement, the bottom set receives the washer and pierces the hole. The action described is very fast; the various movements being almost simultaneous.

Automatic Clamper

With the use of the clamper, none of the material is punched out as is ordinarily done on other types of machines on the market, thus leaving all the material around the eyelet or grommet neck, resulting in the strongest possible setting.

Specifications

| Height | 55″ |

| Weight | 384 lbs. |

| Throat Depth | 3″ |

| Stroke | 2″ |

| Floor Space | 18″ x 23″ |

| Speed | 175 R.P.M. |

| Standard Motor | 1/4 H.P., 1140 R.P.M., 60 cycle, 110-120 volts, A.C., Single phase. 1/3 H.P. on No. 2 Grommet. |