The perfect die-cutting machines for your business

Contact Us For A Custom Quote

Die Cutting Machines

We provide Atom & USM die cutting machines with hydraulic swing arm clickers, traveling head, and beam presses for any application. They are perfect machines for die cutting leather, plastic, vinyl, rubber, cork, and other materials.

Die cutting is the process of using a die to shear webs of low-strength materials, such as rubber, fiber, foil, cloth, paper, corrugated fiberboard, paperboard, plastics, pressure-sensitive adhesive tapes, foam and sheet metal. In the metalworking and leather industries, the process is known as clicking and the machine may be referred to as a clicking machine. When a dinking die or dinking machine is used, the process is known as dinking. Commonly produced items using this process include gaskets, labels, corrugated boxes, and envelopes.

Die cutting started as a process of cutting leather for the shoe industry in the mid-19th century. It is now sophisticated enough to cut through just one layer of a laminate, so it is now used on labels, stamps, and other stickers; this type of die cutting is known as kiss cutting.

Die cutting can be done on either flatbed or rotary presses. Rotary die cutting is often done inline with printing. The primary difference between rotary die cutting and flatbed die cutting is that the flatbed is not as fast but the tools are cheaper. This process lends itself to smaller production runs where it is not as easy to absorb the added cost of a rotary die.

-

-

-

-

-

-

-

-

-

Die Cutting Machines

Atom SE Series: Oildynamic Clicking Die Cutting Press With Turning Arm

Rated 0 out of 5Read more -

Die Cutting Machines

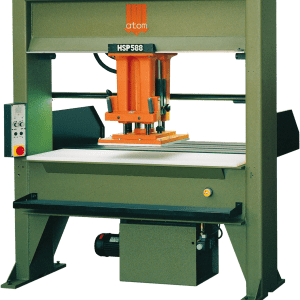

Atom HSP588: Oildynamic Die Cutting Press With Movable Trolley

Rated 0 out of 5Read more -

Die Cutting Machines

Atom SP588: Oildynamic Die Cutting Press With Movable Trolley

Rated 0 out of 5Read more -

Our clients say

We have over 25 years of experience with top business professionals

Parker Collins

We couldn't be happier with our business relationship and fully recommend RSK Sales to any person or company in need of the products they offer.

John Seebock

We have made several purchases of new and used equipment from RSK. In each case we received exactly what we expected and always in a timely manner. Very easy to work with.